Turner’s Cube pencil sharpener [Spring 2022]

Course: Making Your Product at Scale

Task: To create a product concept and plan to manufacture at scale, by also designing its BOM, tooling, assembly line, testing rig, and packaging.

Material: Aluminum

The aim of this project was to tap into the luxury stationery and desk goods market by transforming a traditional CNC/manual machining project into a polished yet practical desktop item.

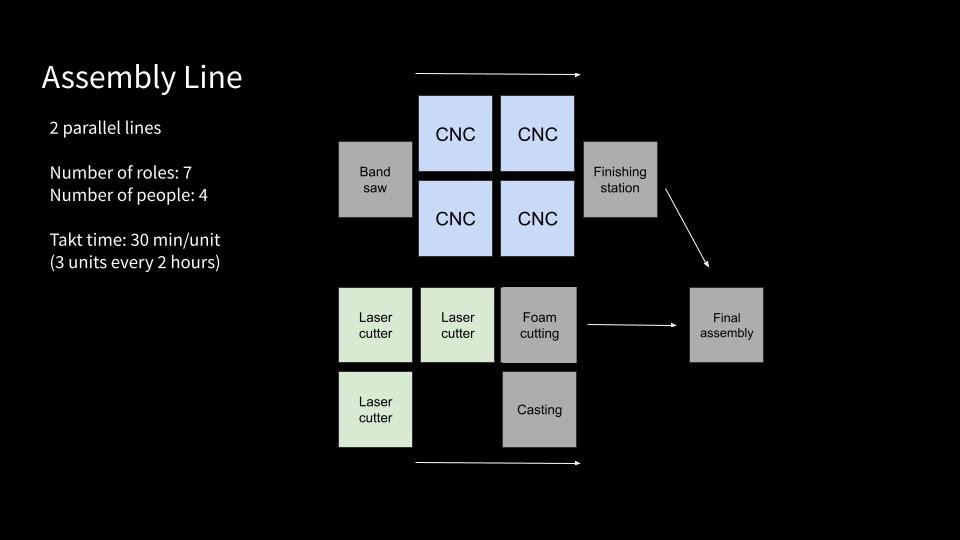

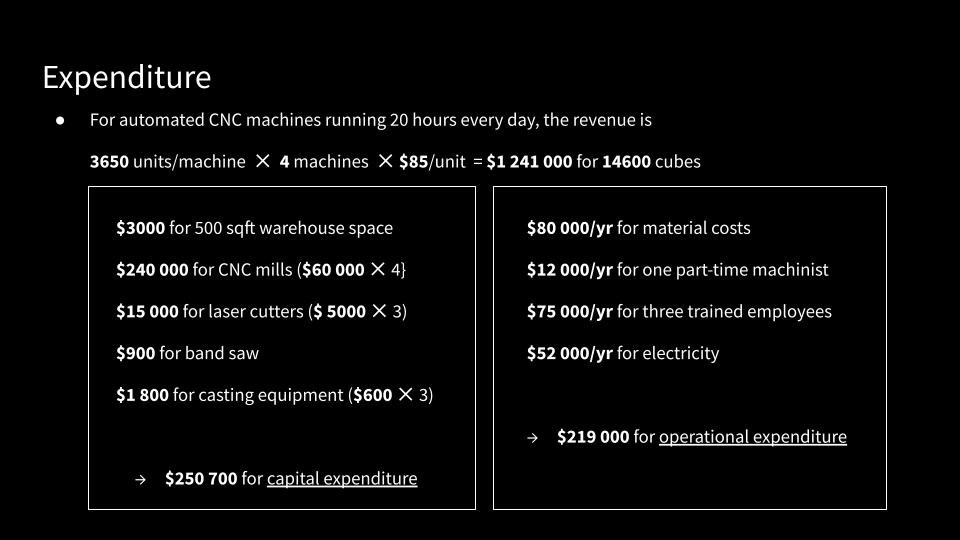

Taking into account the number of chief executives (200 000) and higher education faculty members (1.5 million) in the USA, an estimated market size of 800 000 was selected. For this reason, the initial scale of production is 14 000 units in one year, and 150 000 by the end of five years. An idea for an assembly line consisting of automated CNC and laser cutting (among other stations) was developed in order to reach this target.

Prototyping process

The demo cube was prototyped using manual machining methods.

1)

Creating CAD to dimension, and engineering drawing for reference

Tools: SolidWorks

2)

Cutting 2x2 aluminum stock material to rough dimension, removing burrs

Tools: Horizontal band saw, belt sander

3)

Facing six sides of cube to create 2x2x2 dimensions and smooth machine finish

Tools: Manual knee mill

4)

Finding center of each face, placing stop, and drilling 3 center holes

Tools: Manual knee mill, Vernier calipers

5)

Using two differently dimensioned end mills to create larger circular cuts (slowly revealing smaller cubes within) on six faces, measuring at each step

Tools: Manual knee mill, Vernier calipers

6)

Sanding sides with varying grains and polishing with silicone

Tools: Sandpaper, silicone metal cleaner

7)

Filing sharpener attachment so that diagonal dimension can be press-fit into center hole radius without gaps

8)

Aligning the sharpener hole and adhering it to the inner portion of the smallest center cube.